Introduction

Bird caging, also known as lantern or basket deformation, is one of the most severe forms of distortion observed in rotation-resistant wire rope.

But what causes bird caging? How can you reduce the likelihood of this type of wire rope deformation occurring?

Here are the nine most common causes of birdcage deformations in rotation resistant wire ropes.

Bird Caging in Wire Rope

What is Bird Caging?

Bird caging is a specific type of wire rope distortion that causes a section of rope to appear like a birdcage. It is one of the most distinct types of wire rope deterioration and also one of the most severe. Bird caging calls for the immediate removal of the rope from service.

The Causes

1. A mismatch between rope diameter and drum groove dimensions.

As specified in wire rope standards such as EN 12385:4, API 9A, ISO 10425, and ISO 2408, many drum-grooving systems are made to a higher tolerance than the general diameter tolerance of 0/+5%. Quality, high-performance crane rope is manufactured to a +2/+4% tolerance to meet the closer groove tolerances.

Solution: Ensure drum groove dimensions match rope diameter and take into account groove tolerances when purchasing your wire rope!

Bird Caging in Wire Rope

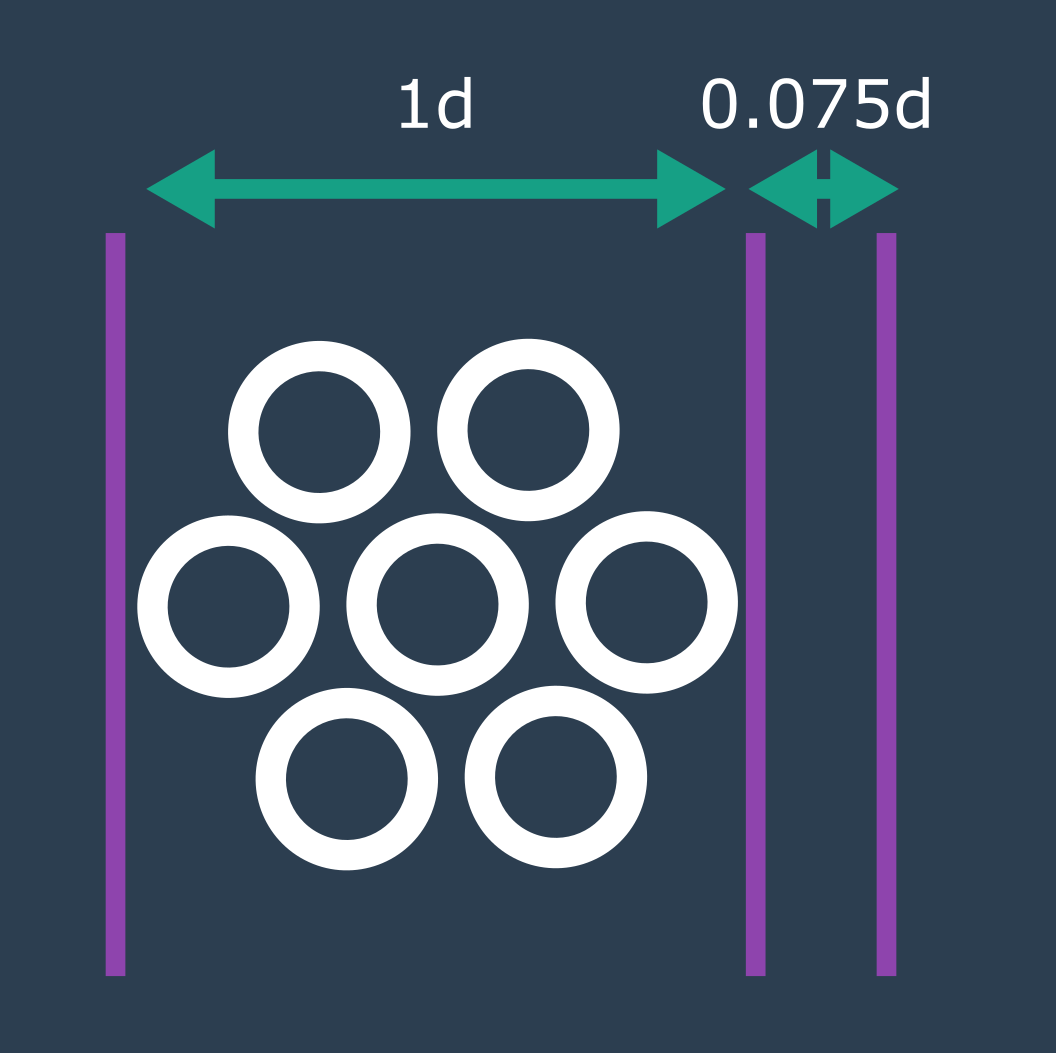

2. Using wire rope with sheave grooves inappropriate for the rope diameter.

The correct sheave groove tolerance is the wire rope's nominal diameter + 7.5% for most applications. Sheaves that are too tight or too big can cause birdcage deformations.

Bird Caging in Wire Rope

Solution: Ensure your sheaves are of the appropriate size for your rope.

Diagram illustrating the correct sheave tolerance for your wire rope.

3. Poorly designed cranes or badly planned modifications.

Poorly designed cranes or badly planned modifications can result in excessive fleet angles leading to the accumulation of turn within the wire rope.

Solution: Contact your crane manufacturer to see if there is a solution, for example, modifying rope length.

4. The rope is installed incorrectly in the crane reeving.

Incorrect reeving installation can lead to inter-rope contact when under load. Inter-rope contact typically occurs between vertical falls. Inter-rope contact leads to cross over of the ropes => cabling.

Solution: Ensure your wire rope is installed correctly in the reeving. We will produce another article covering this in later updates. (You can sign up to receive email notifications at the bottom of this blog!)

5. Other installation problems.

Incorrect installation of the wire rope can lead to induced turn from the word go. Installing wire rope from a supply reel at an angle, or from too short a distance can lead to the build-up of turn.

Solution: Ensure you minimise any angle when installing the wire rope and that you leave enough distance between the supply reel and the drum. We will produce an article on rope installation in a further update.

Get your spooling right to help prevent bird caging.

6. Your supplier may have supplied wire rope with induced turn.

This can occasionally happen, particularly if the supplier is not experienced in supplying high-performance ropes.

Solution: Return the rope to your supplier to re-reel, or run it onto an empty reel yourself to remove turn if you are short on time.

7. Internal rope deterioration.

Internal rope deterioration can create an imbalance between the inner and outer layers of strands.

Solution: Utilise internal inspection techniques as detailed in ISO 4309, or use Magnetic Resonance Testing.

8. Manufacturing fault.

Although manufacturing faults are quite rare, they are certainly possible. Bird caging may manifest quickly in this case.

Solution: In the weeks/months immediately after installation, monitor your rope closely.

9. Incorrect shortening.

When shortening wire rope, both ends must be secured properly. Failure to secure both ends of the wire rope correctly can cause layers to move against each other, creating imbalance. In the case of rotation resistant wire rope, this is particularly important.

Solution: Secure both ends of the rope before attempting to shorten it!

Conclusion

Bird caging in wire rope is a life-ending form of deformation. Excessive turn in the rope maybe a precursor to bird caging. Diligent inspection and proper preparation/installation can often prevent this issue from occurring.

Thanks for reading this article! We hope you found it useful!

Again, thanks for reading,

The Rope IQ team.

Want to find out how our software can help your business?

Request a quick 30 minute demo to find out.

Request a Demo