Introduction

In this article, we are going to look at what localised wire breaks mean and the rejection level defined in the international standard ISO 4309.

Wire rope construction and inherent robustness

A wire rope consists of high carbon steel wires helically wound into strands that are then twisted together to form a wire rope. In a typical wire rope construction, we have six strands each containing thirty-six wires. This construction is commonly referred to as a 6x36 and will have a fibre, steel, or polymer-coated steel core at the centre of the wire rope.

The wires in the outer strands of the rope primarily contribute to its overall strength. For this reason, ISO 4309 provides a percentage allowance in terms of broken wires in the outer strands as discard criteria for wire rope. There are some exceptions to this rule, such as filler wires not contributing to the allowable number of broken load-bearing wires.

In a 6x36, there are a total of 216 load bearing wires. If a single wire break occurs at a specific point, the rope would have lost approximately 1/216 of its strength; a minor issue!

The nifty thing about wire rope is that as we move away from the location of a wire break, the helical structure means that the broken wire continues to contribute to the overall strength of the rope. In theory, a rope can deliver its breaking load even if every load-bearing wire is broken at differing points along the length of the rope!

If, however, wire breaks are concentrated in a short length, then clearly we have a more significant loss of strength at this point.

What is a Localised Wire Break?

ISO 4309 defines localised wire breaks as wire breaks that occur mainly in one or two adjacent strands within a lay length (the distance it takes for one strand to twist completely around a rope) where they do not spool on and off the drum. This distance is approximately 6d (six times the rope diameter).

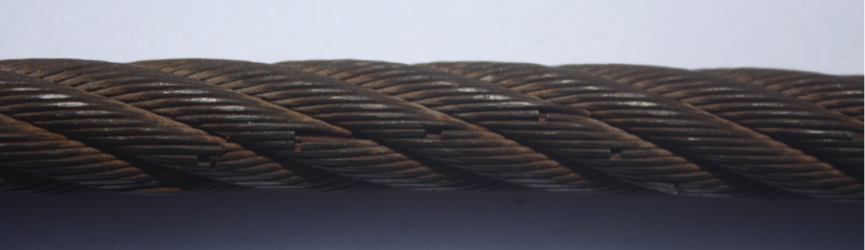

A severe example of localised wire breaks – you’d be rejecting this rope for a number of other reasons as well!

So what does ISO 4309 say in regards to rejection where localised breaks occur? The advice is that the inspector may wish to reduce the random rejection number of broken wires from those listed in tables 3 and 4 in the standard. A 6x36 construction of ordinary or regular lay rope working in steel sheaves on an M1-M4 duty classification has a rejection number of 9 broken wires over 6 diameters.

Important: The above numbers assume that there are no other defects in that area of the rope.

A less severe example but we’d certainly want to take this out of service even if the rope showed no corrosion

Recommendation for Discard

What would we consider to be a suitable number to reject at for a 6x36 – 8,7,6,5?

We can get some guidance from the wire rope sling standard BS EN 13414-1, which allows three broken wires in one strand.

Opinions on this may differ, but in the absence of any closer definition within ISO 4309, it would be a sensible number to apply to crane rope of this construction.

Conclusion

Thanks for reading this far! In this article, we have covered the significance of localised wire breaks and how to spot them. We have also provided a suggested discard criteria for 6x36 ropes.

If you enjoyed the article, be sure to give our LinkedIn page a follow to keep up with our update. You can click the button below if you are not already following our page!

Again, thanks for reading,

The Rope IQ team.

Want to find out how our software can help your business?

Request a quick 30 minute demo to find out.

Request a Demo