Introduction

This article covers exponential deterioration in wire rope, and how if it is not spotted, can quickly lead to sudden rope failure.

By the end of this article, you should understand exponential deterioration in wire rope, how to spot it, and the relevant actions to take.

What causes wire rope to fail?

At a fundamental level, a rope failure can only occur when the load acting on a rope exceeds the actual breaking load (ABL) of that rope.

Therefore, only two things can cause a rope to fail:

- The load increases.

- The ABL decreases.

In most cases, failure will be caused by a decrease in ABL rather than increasing load.

Diagram illustrating the point of failure in wire rope as relating to the ABL and the load.

The factors that contribute to a reduction in ABL are:

- Corrosion (click here to learn more)

- Deformation (like birdcaging)

- Broken Wires (like valley wire breaks or termination wire breaks)

- Wear (click here to learn more)

What is a sudden rope failure?

For the purpose of this article, we will define a sudden rope failure as a rope failure that occurs without prior warning.

Exponential Deterioration

As the condition of a wire rope deteriorates, the likelihood of further deterioration increases. Therefore, the speed of deterioration increases. This acceleration is known as exponential deterioration.

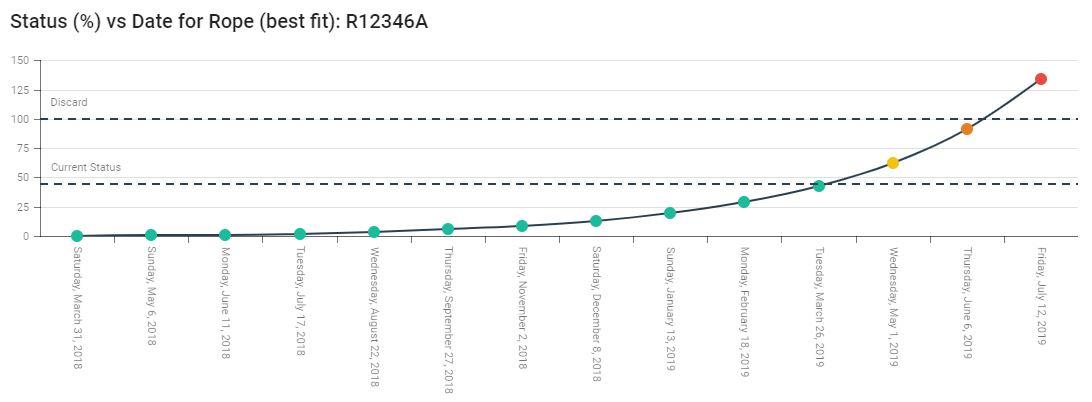

A chart taken from the Rope IQ software showing exponential deterioration in wire rope.

Consider the features in the above chart. We can see:

- The accelerating deterioration of the rope, meaning the reduction in ABL is also accelerating.

- The current status of the rope as calculated using ISO 4309. We can see that the last inspection was performed around 22 March 2019. The rope is safe to use at this point.

- The discard status as defined by ISO 4309. We can see that the rope is predicted to become unsafe around 10 June 2019.

The takeaway from this chart is that the rope has gone from a very safe condition to a dangerous one within two months. The rope would likely be in terrible condition before the next inspection if the usual 6-month inspection period was employed.

Actions to Take

When making rope decisions, it is essential to not only look at the last inspection but to also look at previous inspection history. Without doing so, you may not spot exponential deterioration, which is endemic in the causes of sudden rope failures.

It is necessary to utilise an inspection framework that allows you to quantify the condition of the rope, to spot exponential deterioration. The framework could be ISO 4309, or the use of more quantitative methods of inspection such as NDT.

If you spot exponential deterioration, you may need to ramp up the frequency of your inspections to ensure the rope does not reach a dangerous condition.

Another slightly more expensive option is to use a continuous monitoring technique.

Getting to the point...

The purpose of this article is to highlight how some 'sudden' rope failures are not sudden whatsoever and are sometimes highly predictable.

With proper analysis of inspection data, and by taking a 'time-line' approach to interpreting results, the probability of the occurrence of a sudden rope failure can be reduced dramatically.

Conclusion

Thanks for reading this far! In this article, we have covered exponential deterioration in wire rope, how to spot it, and some actions to take to deal with it.

Thank you for taking the time out of your day to read this article! If you found it useful, give our LinkedIn page a follow so you can keep an eye out for our updates. You can find our LinkedIn page here.

Again, thanks for reading,

The Rope IQ team.

Want to find out how our software can you reduce the chance of sudden rope failures?

Request a quick 30 minute demo to find out.

Request a Demo