Introduction

By the end of this post, you should be able to identify the different types of wire rope corrosion and take the appropriate action to improve your safety.

This post covers the different types of corrosion and what actions to take if you encounter them during wire rope inspection. The post deals with crane rope inspection specifically.

Corrosion (amongst other things) in wire rope

We will cover the three different types of corrosion as specified in the international standard covering wire rope inspection (ISO 4309).

Types of Corrosion

The three different types of corrosion are:

- External Corrosion- Corrosion visible on the exterior of the rope.

- Internal Corrosion- Corrosion visible below the outer strands of a rope.

- Fretting Corrosion- Corroded matter formed by friction when wires in a rope rub together (think sawdust after sanding a plank of wood).

Important: All actions listed below apply only if the rope does not exhibit other forms of deterioration.

External Corrosion

None

Symptoms: No corrosion visible on the exterior of the rope after wiping it clean.

Actions to take: None

ISO 4309 Wire Rope Status: None- does not contribute to the rope's overall status of deterioration.

No External Corrosion in Wire Rope- No corrosion visible on the rope after wiping it clean.

Heavy

Symptoms: The surface of the wire rope displays surface oxidation: the rope is rusty. The rope will also be rough to touch.

Actions to take: Monitor the rope more closely for an increase in the level of corrosion.

ISO 4309 Wire Rope Status: Heavy- adds 60% to the overall status of the rope.

Heavy External Corrosion in Wire Rope - Clear signs of external corrosion.

Severe

Symptoms: Heavy pitting and slack wires.

Actions to take: Remove the rope from service immediately. The rope is dangerous to use.

ISO 4309 Wire Rope Status: Severe- adds 100% to the overall status of the rope.

Severe External Corrosion in Wire Rope - Heavy pitting and slack wires.

Internal Corrosion

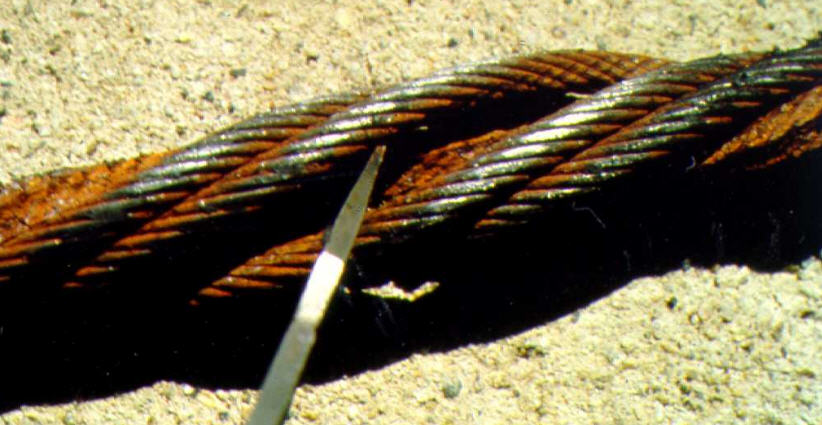

Severe

Symptoms: Corroded matter emanating from the valleys between strands.

Actions to take: Discard immediately or perform a thorough internal examination of the rope.

ISO 4309 Wire Rope Status: Severe- adds 100% to the overall status of the rope unless internal examination reveals no issues.

Internal Corrosion in Wire Rope - Corroded matter emanating from the valleys

Fretting Corrosion

Severe

Symptoms: Similar to internal corrosion but with the presence of dry red powder.

Actions to take: Discard immediately or perform a thorough internal examination of the rope.

ISO 4309 Wire Rope Status: Severe- adds 100% to the overall status of the rope unless internal examination reveals no issues.

Fretting Corrosion in Wire Rope - Dry red matter emanating from the valleys

Slideshow

All of the information above is summarised in this slideshow. Feel free to download it and distribute it to your co-workers!

Download/ShareConclusion

Thanks for reading this far! We appreciate your effort in trying to improve safety in your workplace!

Wire rope corrosion can be an insidious thing, and without proper care and attention, accidents can happen.

You should now be able to correctly identify and act upon the different types of wire rope corrosion when performing an inspection.

Again, thanks for reading,

The Rope IQ team.

Want to find out how our software can help your business?

Request a quick 30 minute demo to find out.

Request a Demo